CHEMOXY OSR Floorings (Oil Resistant Flooring & Solvent Resistant Flooring)

Chemoxy Flooring specializes in crafting high-quality oil resistant flooring and solvent resistant flooring solutions, catering to industries requiring durable and resilient surfaces. Our expertise lies in delivering flooring systems that effectively withstand the harshest environments, providing unmatched protection against oils, solvents, and chemicals.

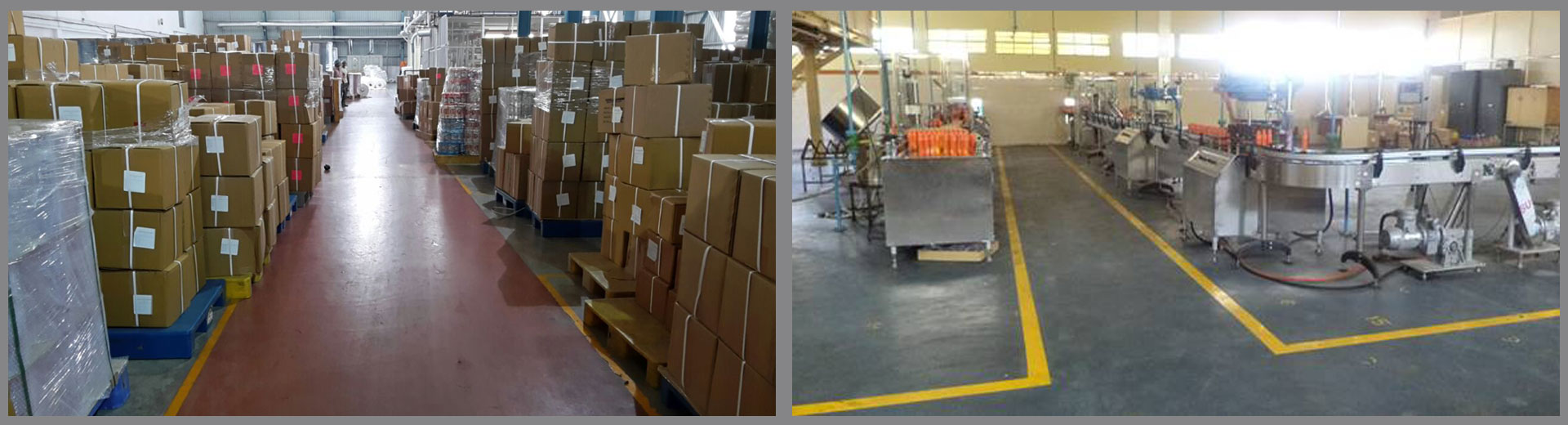

Oil resistant flooring from Chemoxy is engineered to combat the detrimental effects of oil spillage and exposure. These specialized floors act as a barrier, preventing oil seepage and maintaining the integrity of the substrate beneath. Our flooring solutions are meticulously designed to resist oil penetration, making cleanup effortless while ensuring the longevity of the flooring itself. Industries dealing with machinery, automotive, or manufacturing processes benefit immensely from this protective flooring, which minimizes maintenance and enhances workplace safety.

Similarly, our solvent resistant flooring solutions offer superior defense against a spectrum of aggressive chemicals and solvents. These floors are engineered to endure constant exposure to various corrosive substances without compromising their structural integrity. Whether in laboratories, pharmaceutical facilities, or chemical plants, our solvent-resistant flooring provides an impermeable shield against corrosive agents, ensuring a safe and durable working environment.

Chemoxy OSR floor composition are revolutionary chemically formulated Industrial Heavy Duty flooring which are shock resilient, anti- skid and fire Proof. The floor requires no wet curing & achieves early high strength.

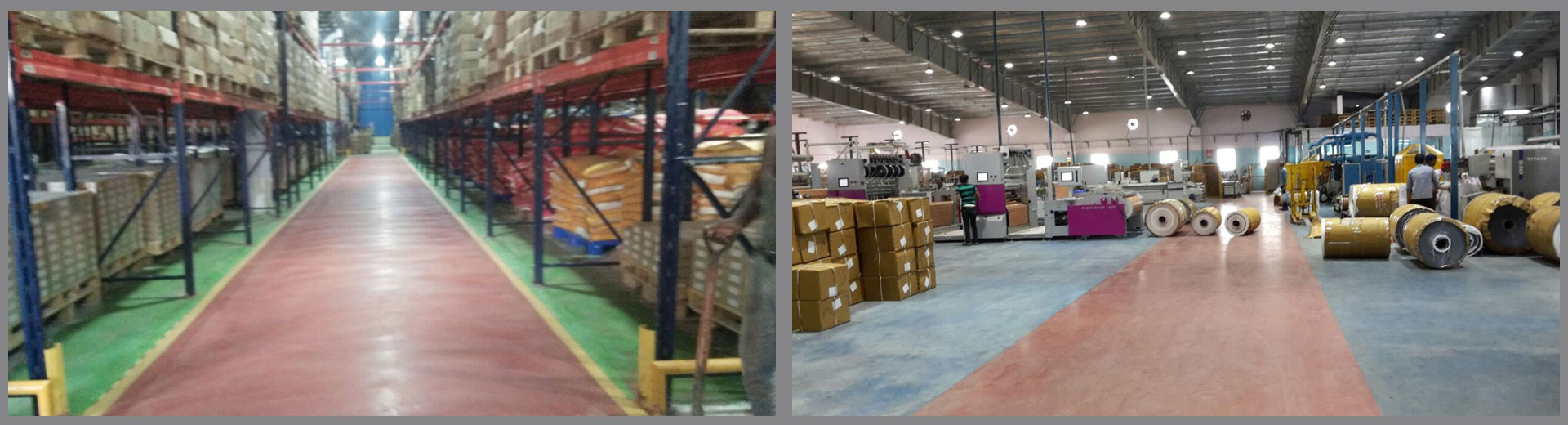

Chemoxy Flooring can be laid on any sound surface like concrete, metal & wooden floors. Chemoxy Floors are carried out with manual & power troweled finish and is available in different colours. Ideal for trolley / forklift / stacker movement in factories, warehouses, store areas and for areas where dust free floors are required as the floor composition does not generate dust. Fast setting & curing in 24 hrs allows continuity of your production in running plant.

This monolithic jointless floor has a tendency to absorb mechanical vibrations (shock resilient). In addition to the above the floor is termite/rat proof & insect repellant. Apart from the engineering companies & warehouses, chemoxy floors are widely used in printing & packaging companies due to its resistance to oil, grease & solvent etc.

The floor does not peel off or delaminate having excellent load bearing propensity and are anti skid in nature. the floor has negligible expansion / contraction thus marking it easy to repair.

- 1

- Monolithic Joint less Floor

- 2

- Shock Resilient

- 3

- Termite / Rat Proof & Insect repellent

- 4

- No Curing required & non cracking floor

- 5

- Resistant to oil & grease solvent etc

- 6

- Anti skid & fire resistant

- 7

- Easily Repairable

- 8

- Load Bearing propensity is excellent

- 9

- Dust Proof floor (Does not generate dust)

- 10

- Ideal for trolley / Stacker / Forklift Movement